Our experience, engineering and planning make the difference.

What is an Electrical Control Room?

When it comes to critical processes, control rooms are essential to efficiently and effectively monitor operations as well as make accurate decisions. The problem is, incorporating them into a facility using traditional construction methods is costly and time-consuming.

With CID Associates, you can get a space where your people can keep tabs on vital functions at a low price point and in short order. We’re experts at designing prefabricated metal structures to serve as modular control rooms, which provide noise and environmental protection for employees and equipment. Best of all, with many material and construction choices available, they can efficiently be designed to fit into just about any location and endure even the harshest conditions. As a leading power control room manufacturer, CID Associates is able to help you with all your electrical control room needs.

What is the Purpose of an Electrical Control Room?

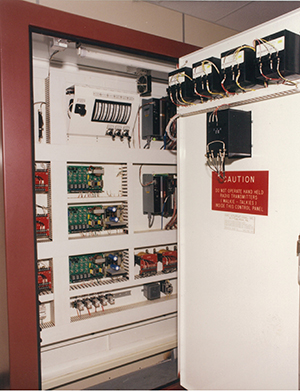

The main purpose of an electrical control room is to provide a centralized place where multiple tasks, information streams, or operations are observed. Depending on the application, they may contain computer systems, surveillance devices, measuring equipment, operating systems, and emergency response indicators.

Whether for monitoring, responding, controlling, collaborating, or communicating, these spaces have been shown to promote more efficient work and better decision-making. That’s why they’re perfect for many uses.

- Aerospace

- Aviation

- Emissions Monitoring

- First-Responders

- Engineering

- Energy

- Financial Services

- Food And Beverage

- Forestry

- Government

- Healthcare

- IT

- Manufacturing

- Metals Processing

- Mining

- Military And Defense

- Networks And Operations

- Pharmaceutical Production

- Power Generation

- Petrochemicals

- Security

- Stadium Or Arena Operations

- Transportation

- Wastewater Processing

- Water Management

There’s an ever-increasing number of applications to manage in a world where technological advancement moves at a breakneck pace. As a result, today’s power control rooms need to be versatile, customizable, and scalable for future trends. That’s where prefab electrical control rooms from CID Associates come into play.

Benefits Of Prefabricated Control Rooms

Prefabricated modular buildings are a great way to add a control room to your application without the cost or delays of traditional construction methods. They’re fabricated in sections following client requirements at an offsite facility, and the pre-built sections are moved to the desired location for assembly.

There are many advantages to using industrial crane-liftable buildings for control room purposes.

- Reduces Noice

- Protects Equipment

- Cost-Effective

- Flexible

- On-Demand Floor Space Expansion Or Contraction

- Environmentally Friendly

- Consistent Quality

- Minimal Site Disruption

- Fast Construction Time

- Improves Safety

Top Modular Electrical Control Room Manufacturer

As a leading electrical power control room manufacturer, CID Associates specializes in manufacturing modular control rooms to meet client-specific needs. We develop the best pre-built modular structure for your process using a proven consultative approach that addresses performance, fitment, longevity, and safety.

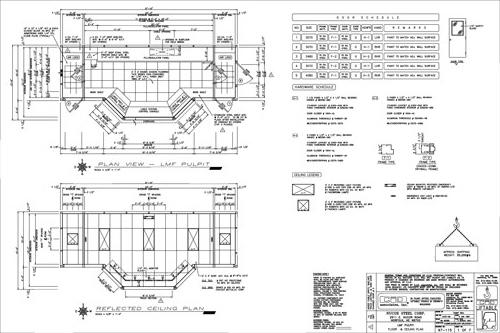

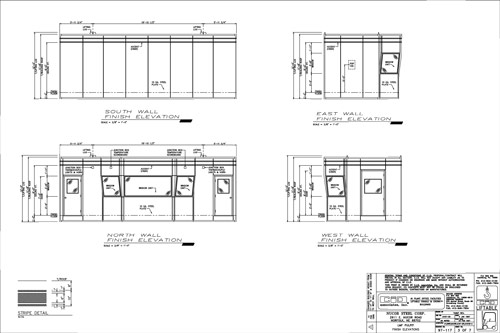

All crane-liftable modular buildings are constructed from a durable welded skeleton of 1/4” tubular steel. This continuously welded outer steel plate skin creates impervious wall, roof, and floor sections. They can be manufactured up to 16 feet in width, incorporate windows or other features, and be painted with unique colors.

Safety, conformance to standards or specifications, and access to vital information are paramount for control rooms. What is needed changes by the industry, and CID Associates is happy to incorporate custom features into your control room design. Examples include:

- Electrical Control Systems

- Pneumatic Control Systems

- Monitoring Systems

- Laboratories

- Stairs

- Catwalks

- Handrails

- Clean Rooms

- Panels

- Landings

- Consoles

- Desks

- Motor Control Centers

As a leading industrial control room manufacturer, quality is paramount. We work with knowledgeable engineers, architects, safety professionals, and independent third-party inspectors to confirm all industry, client, and construction code requirements are met. This includes the latest revisions of the Internal Building Code, International Mechanical Code, International Plumbing Code, International Energy Conservation Code, and National Electrical Code.

Modular Control Rooms Design & Features

Each building incorporates a heavy-duty, continuous welded steel skeleton of 1/4" tubular steel. The exterior steel plate skin is continuously welded to create weather-tight wall, roof, and floor sections. To the left and right of the main operator's viewing area are two airlocks. The airlocks play an intricate part in reducing sound and controlling dirt and dust contaminants that may cause problems with computer equipment. The link below also highlights how CID Associates, Inc. assisted our customer by pre-installing an Operators Control Console and Motor Control Center.

Keep Processes Under Control With CID Associates

At CID Associates, we don’t have a job to do until you need a prefabricated modular control room for your facility or job site. That’s why your challenges are ours, and your deadlines motivate us.

Contact us to learn more about modular control rooms.

States We Work In:

Alabama, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Idaho, Illinois, Indiana, Iowa, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Mexico, Michigan, Mississippi, Missouri, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Pennsylvania, Rhode Island, South Carolina, South Dakota, Tennessee, Texas, Vermont, Virginia, West Virginia, Wisconsin, Canada, Mexico, and other worldwide installations.

Specifications

- PHASE #1: Basic Structure - Overall Outside Dimension

- PHASE #2: Load Bearing Roof Deck

- PHASE #3: Floor Framing, Finished Floor, Doors, Frames & Acoustics

- PHASE #4: Painting

- PHASE #5: Electrical Package

#1 BASIC STRUCTURE – SINGLE MODULE POWER CONTROL ROOM

- The enclosure to be constructed in unitized form and shall be fully welded, utilizing tubular steel products.

- Unit will have crane lifting lugs fully welded at reinforced vertical members.

- The door openings to have a vertical subframe of 4" tubular steel to prevent deflection, displacement, and twisting of the steel doors and frames.

- Wall system to be utilized within the 4" tubular steel panel superstructure to be CID wall panel.

- Exterior wall panels to be carbon steel plate with continuous weld seams and VOC compliant alkyd industrial enamel finish.

- The 4" wall system to incorporate mineral fiber acoustical insulating blanket.

- This insulation will serve as a thermal barrier, dust barrier, and sound deadener.

- The interior porcelain enamel finish steel hard wall panels are extremely rugged, nonchalking, corrosion resistant, and maintenance free.

- The unitized tubular steel framework is designed for and will accommodate recessed structural steel channels inside the lifting crown framework.

- A 10 gauge carbon steel load bearing roof shall be placed and fully seam welded (continuous) at panel junctures and at the structure periphery.

- The completed roof material system shall be fully load bearing to meet owner specification.

- The completed roof system is weather and water tight.

#3 FLOOR FRAMING, FINISHED FLOOR, DOORS, FRAMES, & ACOUSTICS

- Floor framing materials to consist of tubular steel perimeter base members and structural steel C-channels, located to support exterior undercover as well as the finished floor system.

- Steel C-channels are to be welded to the unit superstructure tubular steel base.

- Finished subfloor of the structure to be steel plate.

- Area between the interior and exterior floors to have mineral fiber insulating material, securely fastened to the understructure of the finished floor system.

- The fire resistant, mildew proof insulation is inert and will provide both sound and thermal protections.

- Exterior doors to be supplied with the enclosure at the entry locations.

- All surfaces receiving coating shall be properly prepared as per paint manufacturer's specifications prior to the application of the first prime coat.

- Paint color selection and accents to be as selected by the owner. Corporate colors and company logos may be provided at no additional charge.

- The CID state of the art liftable building shall be furnished with an integral electrical wiring system, including one 12 circuit, 125 amp rated distribution panel.

- The load center to accommodate duplex wall receptacles with GFI protection where required.

- Surface mount 2' x 4' fluorescent light fixtures will be provided.

- All wiring is to be installed as per NEC code and to be installed with recessed EMT metal conduit.

- Independent electrical inspection certificate may be provided if requested.

- Ceiling mounted dual head emergency light unit is included with lighted exit sign at the door(s).

ADDITIONAL OPTIONS INCLUDE:

- Walkways, stairs, platforms with support structures for elevated installation, and HVAC equipment.

To access a complete specification package please contact CID Buildings and ask to speak with someone in sales.

PDF Downloads

-

Power Distribution Centers — Download